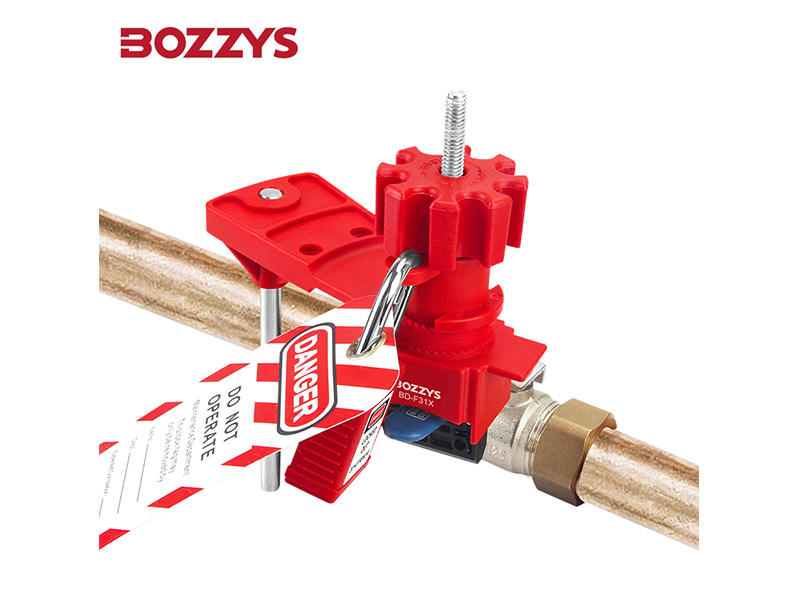

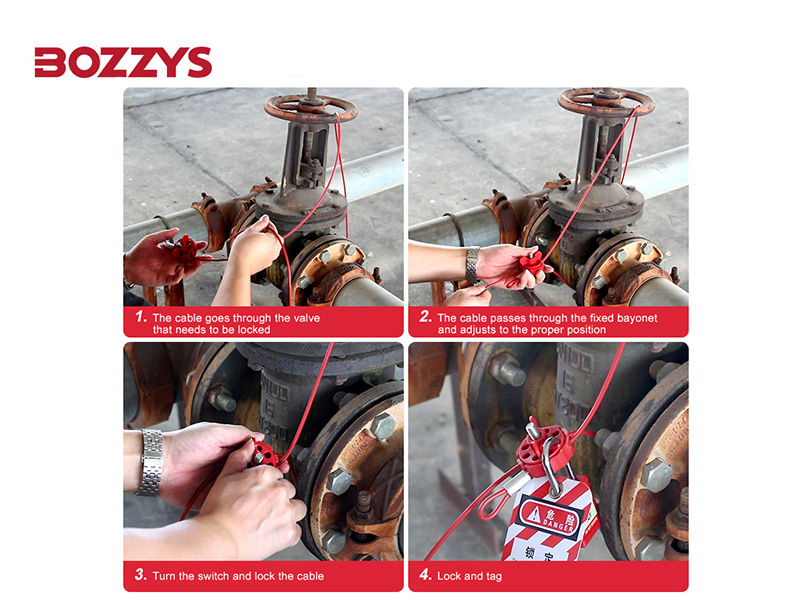

By physically securing a valve in the closed position, they prevent unintentional operation that can lead to accidents. The implementation of valve lockouts is a key safety protocol in industries where heavy machinery is used.

November 05,2025

-1048.jpg)