In industries that use mechanical and electrical equipment, workplace safety is a top priority. An important aspect of safety procedures is the Lockout/Tagout (LOTO), which prevents equipment from being accidentally energized during maintenance or repair. Among the various LOTO devices available, the Cable Interlock (or Cable Lockout) system plays a vital role in effectively protecting multiple energy sources.

A Cable Interlock, commonly referred to as a Cable Lockout, is a flexible and versatile safety device used to isolate multiple energy sources simultaneously. It consists of a durable steel cable and locking accessories that can be passed through switches, valves, circuit breakers, and other energy control points.

Unlike traditional single-point locking padlocks, a Cable Interlock allows workers to lock multiple energy isolation points with a single cable, ensuring complete safety during maintenance.

High-Strength Steel Cable – Resistant to Cuts, Corrosion, and Extreme Conditions.

Locking devices – such as padlocks or combination locks to secure both ends.

Adjustable accessories – including snaps, stops and loops to accommodate a variety of equipment types.

1. Identify energy sources – Identify all switches, valves or circuit breakers that need to be isolated.

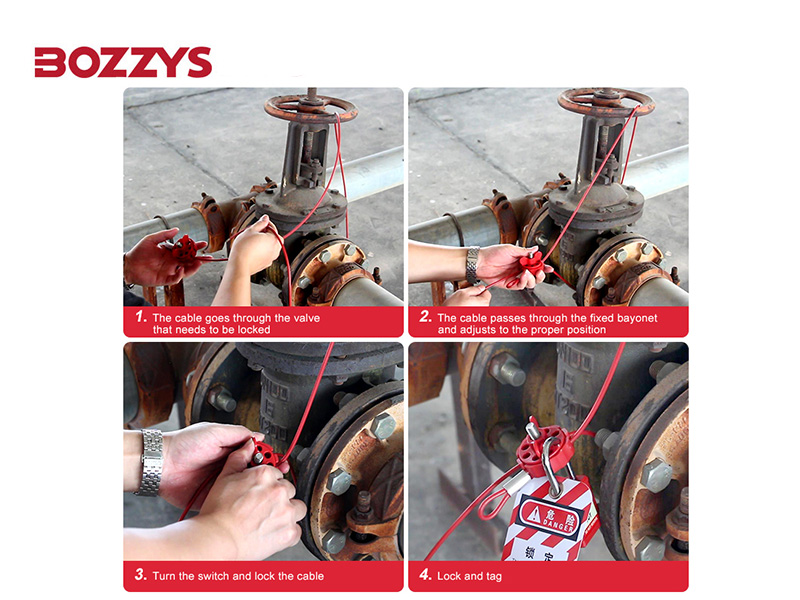

2. Thread the cable – Thread the cable through each energy control point.

3. Secure both ends – Secure both ends of the cable with locks to prevent the cable from falling off.

4. Confirm lock – Ensure that no power source can be reactivated before unlocking.

This method is particularly useful for complex machinery with multiple power sources to ensure that no accidental start-up can occur.

1. Versatile – Can be used on a variety of equipment from switchboards to hydraulic systems.

2. Efficient – Single device can protect multiple isolation points, saving time.

3. Durable – Made of high-strength materials to withstand harsh industrial environments.

4. Safety Compliance – Meets regulatory requirements of OSHA, ANSI and other LOTO programs

5. Enhanced Safety – Prevents unauthorized or accidental re-energization, reducing workplace hazards.

Cable interlocks are widely used in the following industries:

Manufacturing – Locks conveyors, presses and robotic arms.

Electrical Maintenance – Secures circuit breakers and control panels.

Oil and Gas – Isolates valves and pipes during maintenance.

Construction – Prevents machinery from starting during maintenance.

When choosing a cable interlock, consider the following:

Cable length and thickness – Should accommodate the number of isolation points.

Lock type – Keyed, combination or custom lock.

Material quality – Stainless steel or vinyl coated for increased durability.

Compliance – Make sure it complies with relevant safety standards (OSHA 1910.147, ANSI Z244.1).

Conclusion

The cable interlock (cable lockout) system is an essential safety tool for industries that require multiple points of energy isolation. Its flexibility, durability, and compliance with safety regulations make it a top choice for preventing the release of hazardous energy.

By implementing cable lockout in LOTO procedures, companies can improve workplace safety, reduce accidents, and ensure compliance with industry standards.